Component Maker to Build Second Ohio Manufacturing Plant

Stay on top of Logistics News: Get KGR News in your Inbox

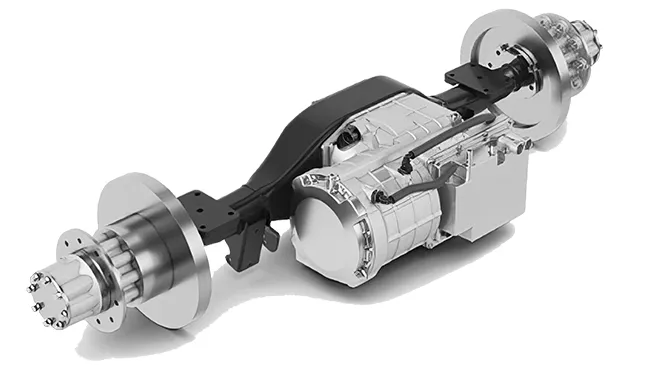

LAS VEGAS — Component maker Schaeffler is developing an electric axle, motor and battery drivetrain package for North American commercial vehicles, up to and including Class 8 trucks, said by executives.

The heavy-duty version of the drivetrain will be ready by September in a demonstrator capacity, Thomas Heck, Schaeffler director, key account management, European and heavy-duty customers, told associates on the sidelines of CES.

Currently, Schaeffler has a Class 2B Ford F-250 demonstrator. With the Ford F-250, the company took the conventional transmission and axle package out and replaced it with a beam e-axle and battery pack, said Heck.

Schaeffler designed its own battery packs. The company bought commercial battery cells and integrated them, said Heck.

Heck

The next step is to take it to the commercial vehicle level at 7.5 tons or 15,000 pounds, with the plan to go all the way up to Class 8, said Heck. The drivetrains will be produced at the company’s current Wooster, Ohio, transmission manufacturing plant, which has 1,800 employees.

But Schaeffler is building a new plant in Ohio to facilitate the program as well, with a location announcement coming in the next few weeks, Heck told TT. That plant will not be in Wooster, he said.

The company picked the unnamed Ohio location because it is close to Schaeffler’s existing knowledge base as well as customers in the Midwest, Heck said. The new plant will be smaller than the Wooster plant, although he declined to say how large it would be.

Image

Schaeffler first unveiled the electric drivetrain concept for light vehicles in 2022.

The motor for each e-axle is built in-house. Commercial cells are merged into battery packs. Commercial production is scheduled to begin in 2025, said Heck.

Some motors have been developed without a magnet, which the company calls “an electrically excited synchronous machine,” Heck said. This is a key technological shift away from rare earth metals and magnets, he added.

technological shift away from rare earth metals and magnets, he added.

A rigid beam, 3-in-1 e-axle. (Schaeffler Group)

Schaeffler is wary of trying to compete with existing lithium-ion battery cell manufacturers; therefore it is developing in-house solid-state cells. Heck said this is a key technology for commercial vehicles because the energy density increases, and the electrolyte is not flammable.

However, commercial production of the solid-state batteries is more than five years out, Heck said.

Schaeffler will not be building charging infrastructure, Heck said. Schaeffler is, however, building hydrogen fuel cell stacks, mostly in Germany, he said. The company is also making electrolyzers that make the hydrogen. There is no timeline as yet for launch of the fuel cells, he said.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

كيفية التسجيل في بينانس وتفعيل الحساب https://accounts.binance.com/ar/register/person?ref=775587485

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Bitcoin Accelerator This tool is designed to prioritize your transaction, ensuring it gets confirmed faster on the network. It’s an essential resource for anyone looking to optimize their Bitcoin experience. Don’t let slow confirmations hold you back; discover the benefits of using an accelerator today!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks!